High pressure within a boiler can be risky, potentially leading to leaks and explosions. Our relief valve is designed to effectively manage excess pressure and ensure safety. Regular professional servicing from our local plumbing company in Mississauga is crucial for maintaining safety standards. Implementing safety precautions is essential when operating under high pressure conditions. Monitoring pressure levels diligently helps to prevent potential hazards. Regular thorough inspections are necessary to uphold the integrity of boiler components. Operating at the optimal pressure level promotes smooth running and efficiency. Detecting pressure issues early on is key to preventing costly damages. Maintaining appropriate temperatures and pressure levels can prolong the lifespan of the boiler. Specific pressure settings are vital for ensuring optimal efficiency and performance. Efficient energy usage not only enhances performance but also helps to reduce costs. Effective pressure management plays a critical role in overall boiler performance. It is important to learn more about proper boiler care and maintenance in order to achieve success.

Contact CAN Plumbing and Drainage for your Boiler Needs

When addressing your boiler needs, reaching out to CAN Plumbing and Drainage in Mississauga is crucial for comprehensive service and expertise. Boilers operate within a specific pressure range, and issues can arise from both high and low pressure levels. High pressure in a boiler can pose dangers such as leaks or explosions. The pressure relief valve plays a critical role in regulating excess pressure within the boiler system. Regular servicing by professionals like CAN Plumbing and Drainage in Mississauga ensures that pressure levels remain safe, mitigating the risks associated with high pressure situations. Contact us to maintain your boiler’s efficiency and safety.

CAN Plumbing and Drainage Services Related to Boilers

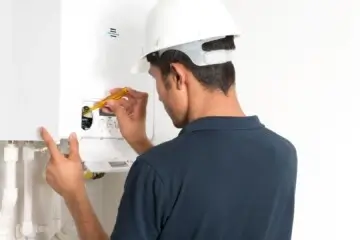

At CAN Plumbing and Drainage in Mississauga, we specialize in new boiler installations, replacements, and repairs. Our team of experienced technicians is well-equipped to handle any boiler-related service you may need. Whether you require a brand-new boiler installed, a replacement for your existing unit, or repairs to ensure peak performance, we are here to assist you.

New Boiler Installations

We specialize in providing comprehensive plumbing and drainage services tailored specifically for new boiler installations. Proper boiler pressure is crucial during the installation of a new boiler to prevent potential issues such as boiler explosions. Our team ensures that the boiler pressure is set according to the manufacturer’s guidelines, reducing the risk of high pressure. We also educate our clients on how to lower boiler pressure if it exceeds safe levels. By following a detailed boiler pressure guide and addressing the causes of high boiler pressure during new boiler installations, we guarantee a safe and efficient system for our customers.

New Boiler Replacements

Efficient integration of new boiler replacements is a core competency of our plumbing and drainage services. High boiler pressure can have detrimental effects on the system, leading to leaks, increased wear, and even boiler failure. If the pressure continues to rise, immediate action is necessary to prevent further damage. Our team has the expertise to address issues related to high boiler pressure effectively, ensuring optimal performance and longevity of the system.

Boiler Repairs

With our specialized expertise in boiler repairs, CAN Plumbing and Drainage Services ensures efficient and effective solutions for any boiler-related issues. High pressure within a boiler system can be detrimental if not managed correctly. Boiler pressure that is too high can lead to various problems, including potential damage to the boiler itself. Our team is well-versed in diagnosing pressure problems and conducting thorough boiler repairs to rectify these issues promptly. By addressing pressure in the system proactively, we mitigate the risk of long-term damage and ensure the best functioning of your boiler. Trust CAN Plumbing and Drainage in Mississauga for expert solutions to maintain your boiler’s efficiency and longevity.

Safety Concerns

Safety concerns can arise when high pressure is exerted on a boiler, necessitating stringent measures to prevent potential hazards. A faulty boiler may result in the boiler pressure dropping unexpectedly, leading to a sudden increase in pressure. If the pressure gets too high, it could pose a serious risk of explosion or other safety issues. Regular monitoring of the boiler pressure is pivotal to make sure it stays within safe limits. Sudden pressure drops can also indicate underlying problems that need immediate attention to prevent accidents. Understanding the risks associated with high pressure is essential for maintaining a safe working environment and preventing catastrophic boiler failures. Prioritizing safety concerns is paramount in the operation and maintenance of boilers.

Maintenance Practices

During our maintenance practices, we conduct thorough inspections of all boiler components on a regular basis to ensure optimal performance and longevity. Monitoring the boiler pressure is crucial for maintaining efficiency and safety. The boiler pressure refers to the pressure levels within the system, which can range from high to low pressure. To prevent issues related to high pressure, we consistently check the boiler pressure gauge and make necessary adjustments. It’s important to be aware that pressure levels can unexpectedly rise, posing potential hazards. By maintaining the right pressure levels and promptly addressing any deviations, we can guarantee the smooth operation of the boiler system and reduce the risk of damage or accidents.

Longevity and Durability

Regular monitoring of operational parameters such as temperature and pressure is crucial to ensure the longevity and durability of the boiler system. High pressure can have detrimental effects on the boiler, leading to issues like pressure loss that can impact the system’s efficiency. Utilizing a pressure gauge enables the maintenance of specific pressure levels within the optimal range, ensuring the proper functioning of the boiler. Fluctuations in water pressure can also influence the performance and lifespan of the system. Therefore, conducting routine checks and maintenance is essential to prevent potential damage and sustain the longevity and durability of the entire heating system.

Efficiency and Performance

Monitoring and maintaining optimal pressure levels in the boiler system significantly impacts its efficiency and performance, ensuring smooth operation and longevity. Regularly checking the pressure inside the boiler is crucial to optimize its efficiency and performance. Excessive pressure can lead to a range of issues, including reduced efficiency and potential system damage. For example, in a combi boiler, the pressure should typically fall between 1 and 1.5 bar. As the water inside the boiler heats up, it expands, resulting in increased pressure. By ensuring that the pressure remains within the recommended range, you can prevent unnecessary strain on the system and uphold the highest efficiency and performance levels over time.

Energy Consumption

Maintaining optimal pressure levels in the boiler system significantly impacts energy consumption, directly influencing operational costs and overall efficiency. Excessive boiler pressure leads to increased energy usage as the system works harder to distribute heat efficiently. This extra pressure can cause inefficiencies in heat transfer, resulting in unnecessary energy consumption. Inefficient energy use not only raises operational expenses but also strains the boiler components, potentially leading to maintenance issues and reduced equipment lifespan. Properly managing boiler pressure is essential for optimizing energy consumption and ensuring efficient heat distribution for hot water and central heating systems.

Frequently Asked Questions About Boilers Near Me

Can High Pressure in a Boiler Lead to Any Long-Term Health Effects for Individuals Using the System?

High pressure in a boiler can lead to long-term health effects for users, as it can cause stress on the system and potential safety risks. Regular maintenance and monitoring are essential to ensure safe operation and prevent health issues over time.

How Does the High Pressure in a Boiler Impact the Overall Efficiency of the Heating System?

Elevated pressure in a boiler can significantly impact the efficiency of the heating system. It can lead to increased energy consumption, reduced heat transfer efficiency, and possible damage to components. Proper maintenance and monitoring are crucial to enhance performance and optimize overall efficiency.

Are There Any Specific Maintenance Practices That Can Help Prevent Issues Related to High Pressure in a Boiler?

Regular monitoring of pressure levels and conducting routine inspections are essential maintenance practices to prevent issues related to high pressure in a boiler. It is important to adjust pressure settings within manufacturer guidelines and ensure proper ventilation. Additionally, regularly testing safety valves and maintaining adequate water levels are crucial steps to avoid problems.

What Are the Potential Consequences of Ignoring Safety Concerns Related to High Pressure in a Boiler?

Neglecting safety concerns associated with high pressure in a boiler can result in severe consequences, such as explosions, equipment damage, and potential harm to individuals. It is crucial to prioritize regular maintenance, monitoring, and adherence to safety protocols to prevent these incidents.

How Does High Pressure in a Boiler Affect Energy Consumption and Utility Costs in the Long Run?

Excessive pressure in a boiler can result in higher energy consumption and increased utility costs in the long run. When the pressure levels are too high, the boiler operates inefficiently, leading to excessive fuel usage. It is essential to monitor and maintain the correct pressure levels to ensure optimal efficiency and cost-effectiveness.

Please rate our website

Let us improve this post!

Tell us how we can improve this post?